Our calculation department answers your problems of optimization, validation of parts or mechanical assemblies, verification of existing systems, such as:

- calculation of loads on shelves

- calculation of process structures

- calculation of storage silos (AAC1, AAC2)

- spreaders

- access ramps

- pressure vessel

- dimensioning of mechanical assemblies

- …

We use powerful numerical calculation tools and implement the most realistic modelling possible. We can handle different types of mechanical problems:

- static

- dynamic

- linear / non-linear behaviour

- thermoelasticity

- structural analysis and sizing (Eurocode)

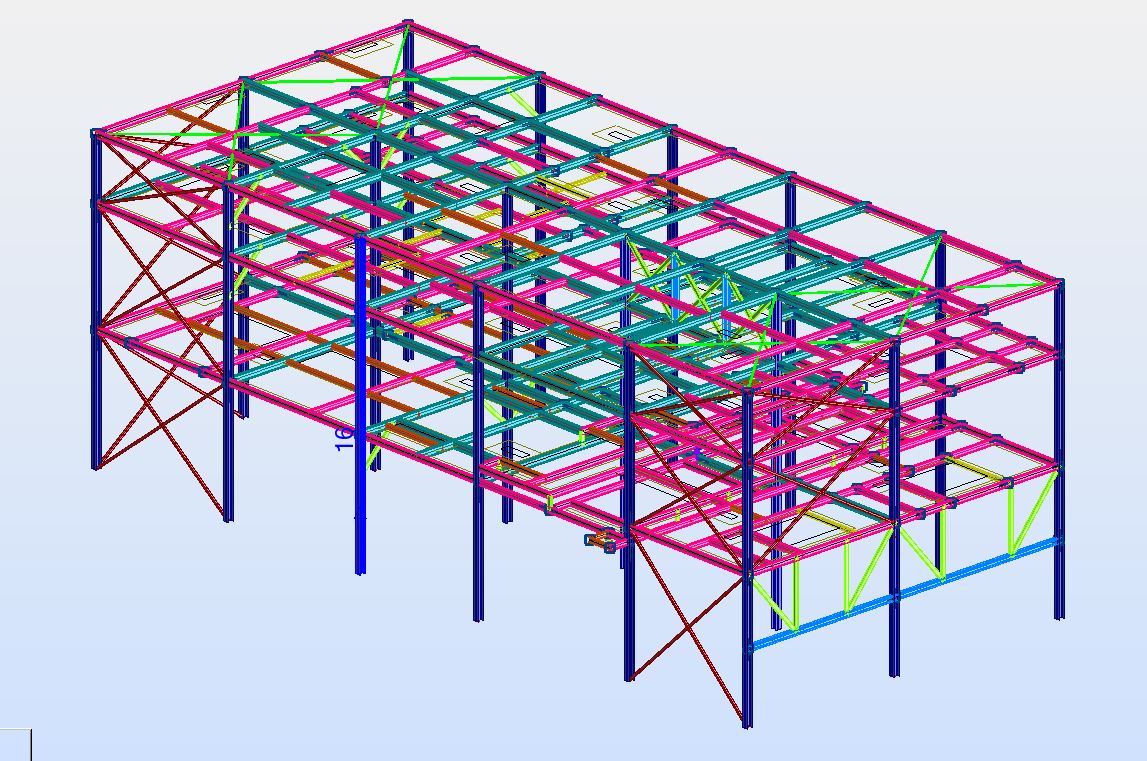

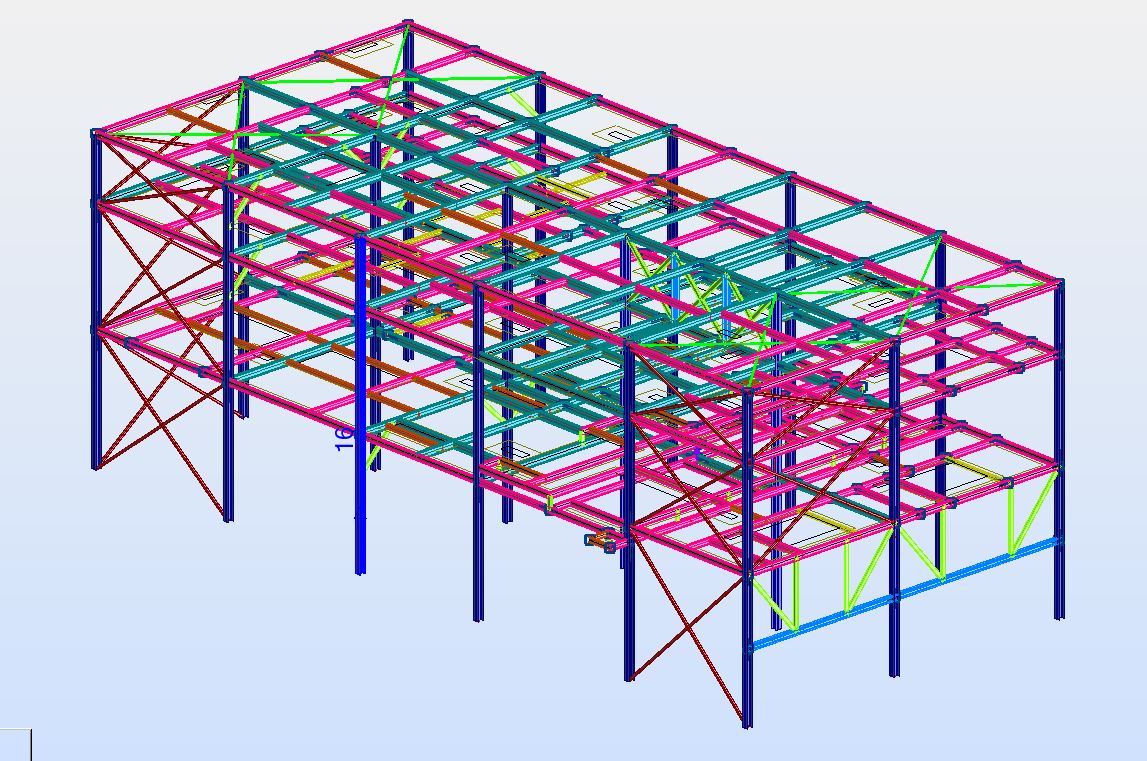

Calculation of structures

Our engineers and technicians can perform the structural calculations of your metal structures and metal silos (cylindrical, rectangular). These sizing are done in accordance with the Eurocode.

The calculations allow us to specify the choice of profiles, materials, bolted and welded joints, anchors.

All the results are then returned to you on a clear and concise calculation note, directly exploitable by the control bodies.

Mechanical components dimensioning

Our teams are also able to bring you their expertise on your machines mechanical sizing :

- Synchronous, asynchronous, step-by-step drives

- Power transmissions

- Guidance

- Pneumatic

- Hydraulics

We are also able to recommend and provide the appropriate equipment by making you benefit from our manufacturer rates.

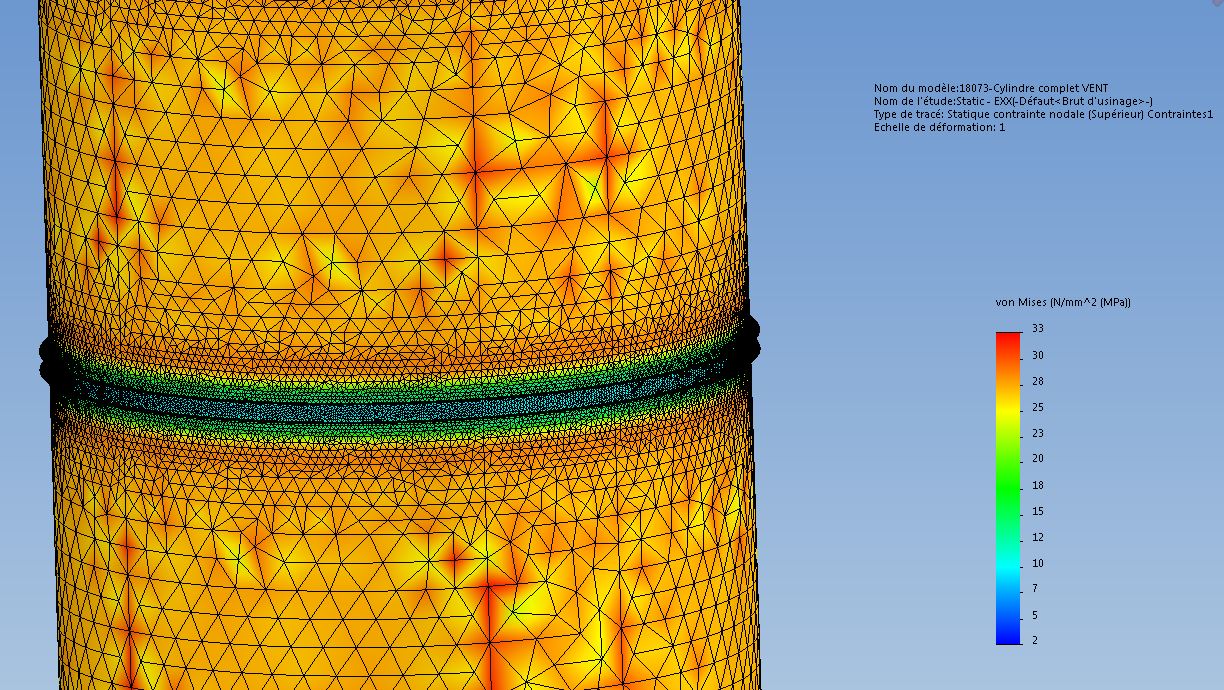

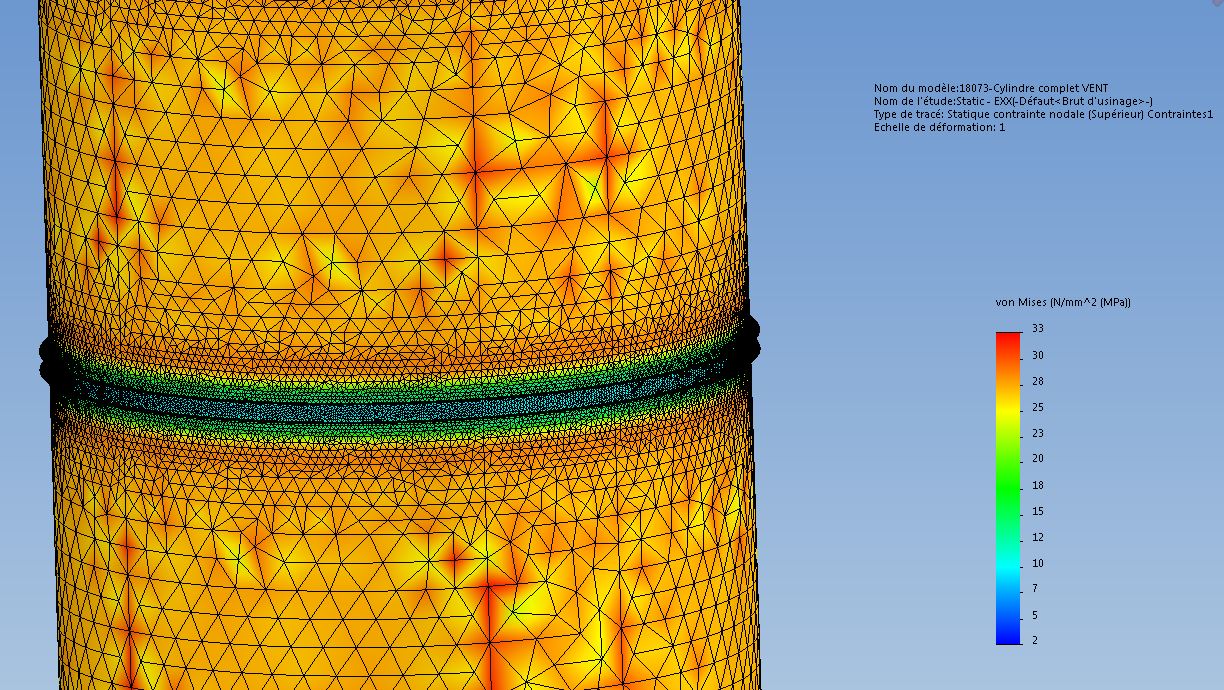

Numerical finite elements simulation

We propose the use of the numerical tool to answer mechanical parts geometry optimization requests in order to reduce the production costs while preserving the functional properties:

- material optimization

- mechanical resistance improvement

- part geometry simplification

- material selection

- obtaining process selection

As such, we can perform different types of analysis:

- static analysis

- dynamic analysis

- thermomechanical analysis

- nonlinear analysis (hyper elasticity, plasticity)

- fatigue analysis