Our clamping machines

The final capacity of your steel beam assembly line is driven by the choice of the clamping machine.

We propose 4 different models of clamping machines :

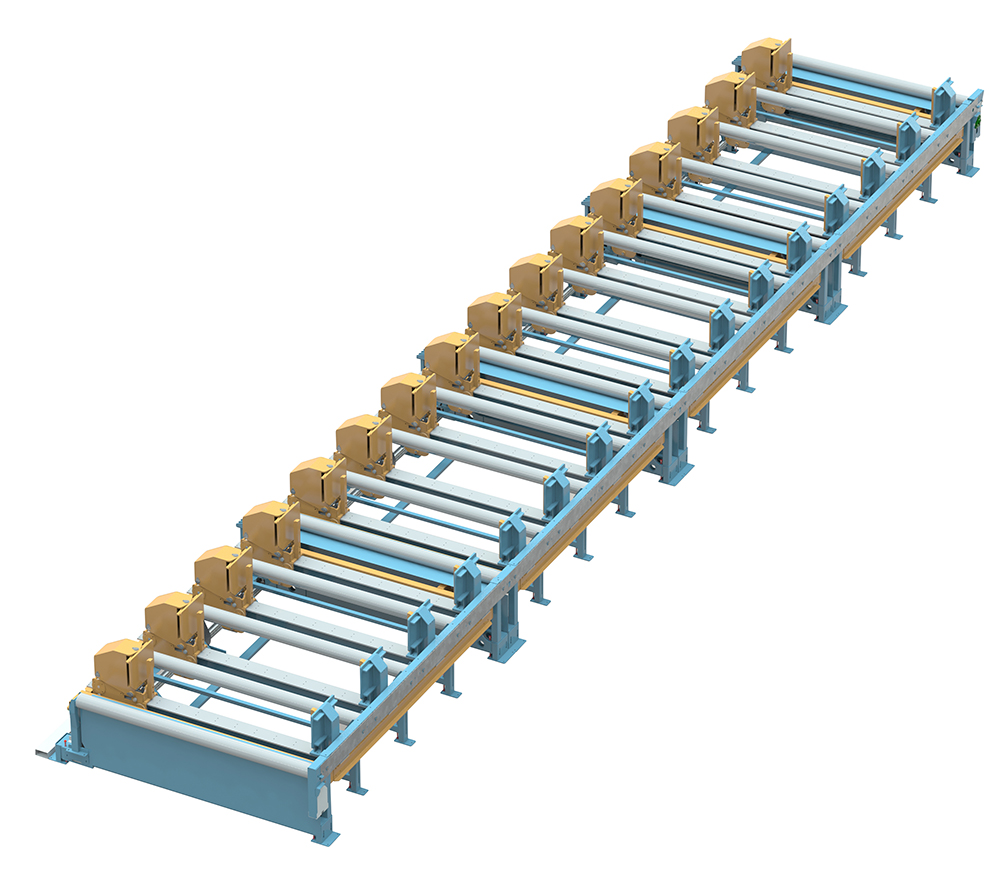

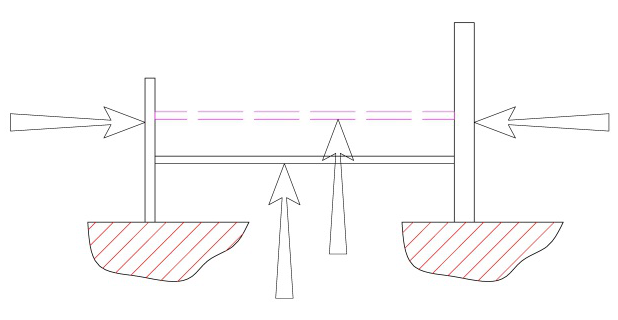

BASEKO Clamping

By group of 4m unit

-

Beam dimensions :

- Feasible section : H or Box

- Length = By group of 4m unit

- Minimum core height = 300

- Maximum core height = 1600 / 2000 / 2500 VR

- Maximum core thickness = 40 mm

- Maximum flange width = 500 mm

- Maximum flange thickness = 50 mm

- Maximum beam linear density = 600 kg/ml

For larger dimensions, please contact us.

Beam Geometry PRS :

- Flange n° 1 : straight position

- Flange n° 2 : any position

- Core : middle or offset position

- Welding (option): tacking or submerged arc welding

Control :

- HMI : touch sensitive display

- Remote access service

- Direct design file transfer : dstv, dxf…

Options :

- Second clamping machine for welding exclusively

- Fastening control on machine with two-hand control (remote control)

- Motorized roller transfer

- Reinforced structure for heavy version (beam linear density = 1500 kg/ml)

- Specific tool for box section

- Wireless HMI

- Tropicalization

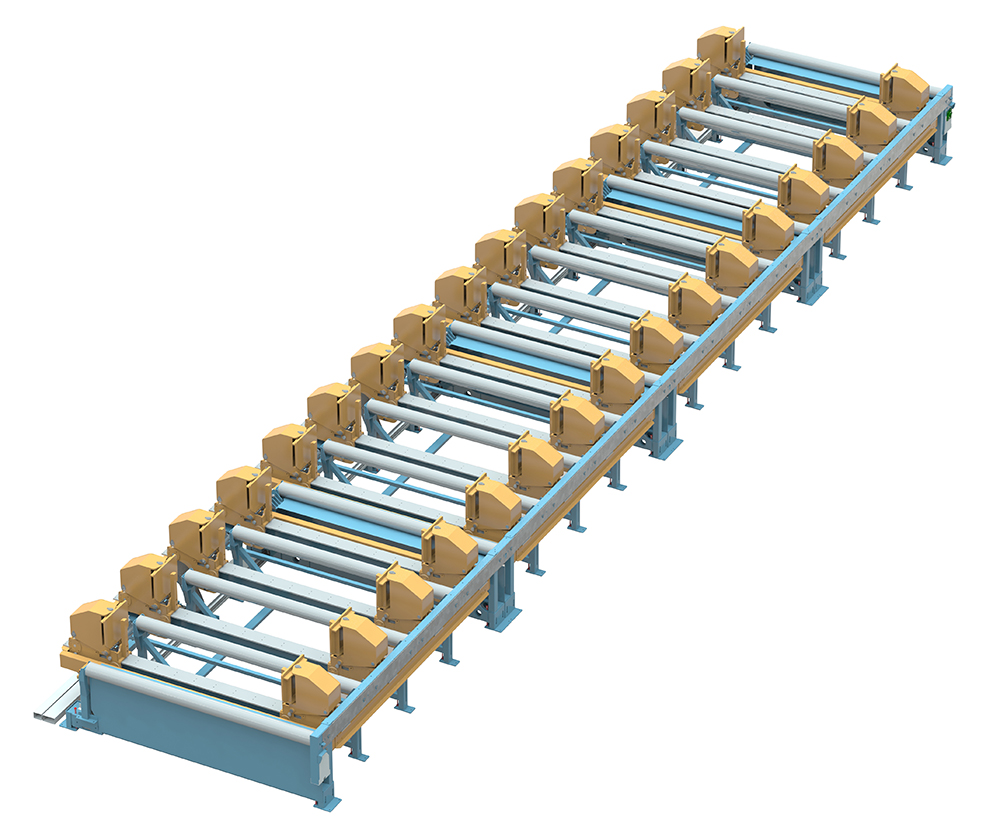

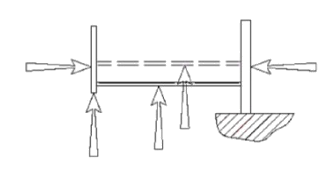

EKOVAR Clamping

By group of 4m unit

-

Beam dimensions :

- Feasible section : H or Box

- Length = By group of 4m unit

- Minimum core height = 300

- Maximum core height = 1600 / 2000 / 2500 VR

- Maximum core thickness = 40 mm

- Maximum flange width = 500 mm

- Maximum flange thickness = 50 mm

- Maximum beam linear density = 600 kg/ml

For larger dimensions, please contact us.

Beam Geometry :

- Flange n° 1 : any position

- Flange n° 2 : any position

- Core : middle or offset position

- Welding (option) : tacking or submerged arc welding

Control :

- HMI : touch sensitive display

- Remote access service

- Direct design file transfer : dstv, dxf…

Options :

- Second clamping machine for welding exclusively

- Fastening control on machine with two-hand control (remote control)

- Motorized roller transfer

- Reinforced structure for heavy version (beam linear density = 1500 kg/ml)

- Specific tool for box section

- Wireless HMI

- Tropicalization

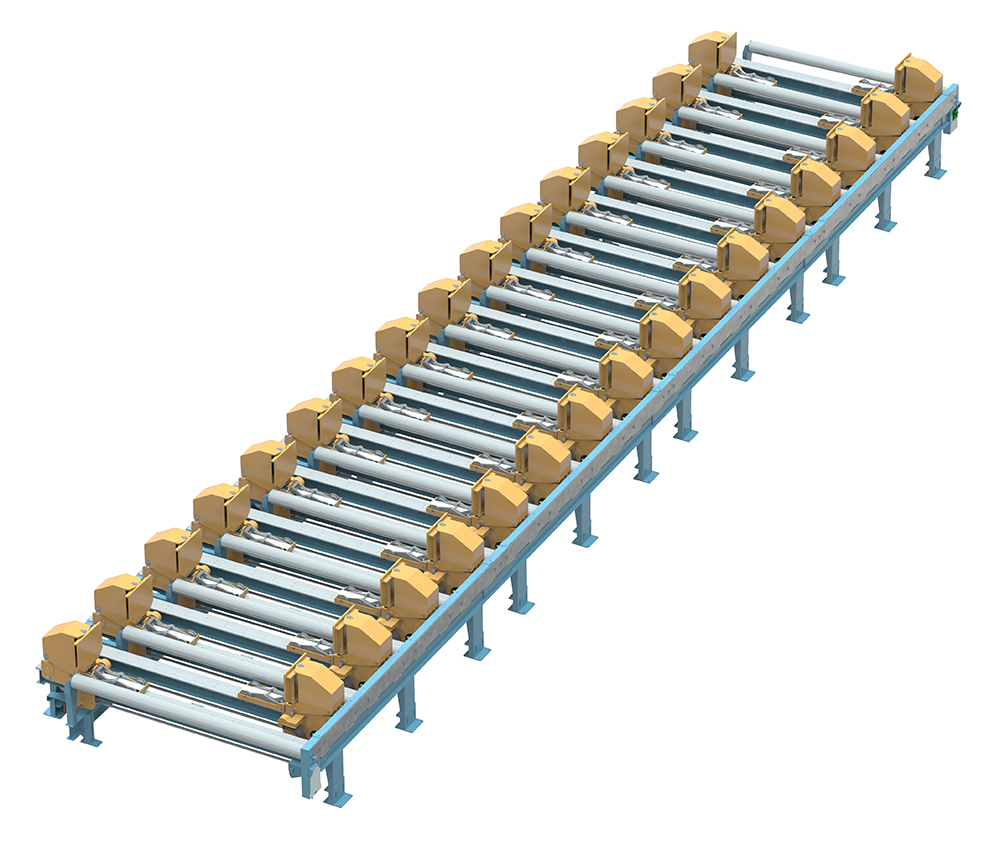

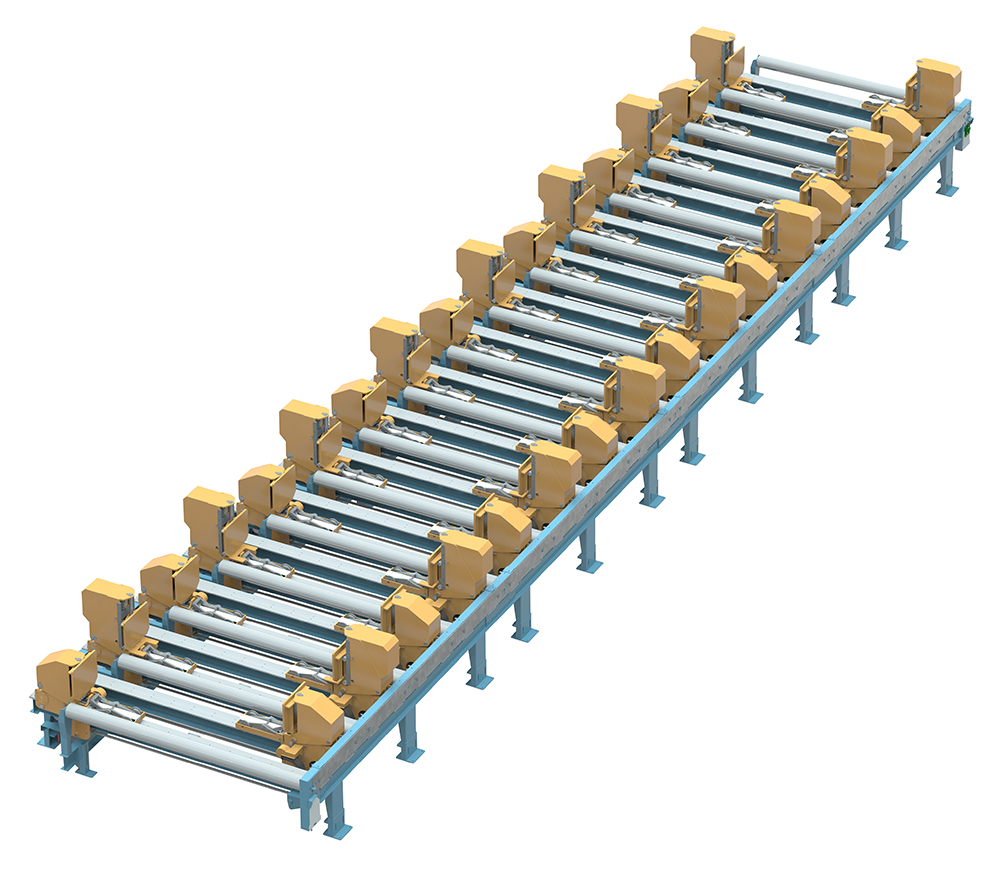

EASYVAR Clamping

Each meter

-

Beam dimensions :

- Feasible section : H or Box

- Length = each meter

- Minimum core height = 300

- Maximum core height = 1600 / 2000 / 2500 VR

- Maximum core thickness = 40 mm

- Maximum flange width = 600 mm

- Maximum flange thickness = 50 mm

- Maximum beam linear density = 600 kg/ml

For larger dimensions, please contact us.

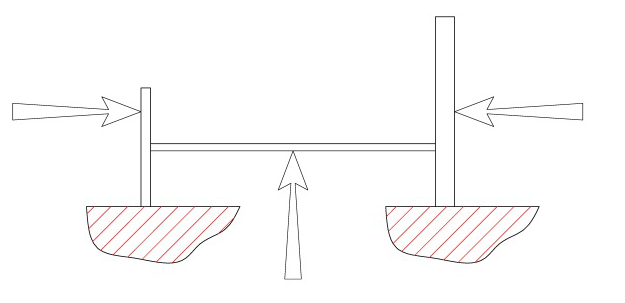

Beam geometry :

- Flange n° 1 : any position

- Flange n° 2 : any position

- Core : middle, offset, inclined position

- Welding (option): tacking or submerged arc welding

Control :

- HMI : touch sensitive display

- Remote access service

- Direct design file transfer : dstv, dxf…

Options :

- Second clamping machine for welding exclusively

- Fastening control on machine with two-hand control (remote control)

- Motorized roller transfer

- Reinforced structure for heavy version (beam linear density = 1500 kg/ml)

- Specific tool for box section

- Wireless HMI

- Tropicalization

- Automatic adjustment and tacking gantry

- Automatic flange standing up

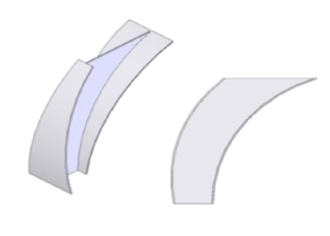

GECKOVAR Clamping

Each meter

Beam dimensions :

- Feasible section : H or Box

- Length = each meter

- Minimum core height = 300

- Maximum core height = 1600 / 2000 / 2500 VR

- Maximum core thickness = 40 mm

- Maximum flange width = 600 mm

- Maximum flange thickness = 50 mm

- Maximum beam linear density = 600 kg/ml

For larger dimensions, please contact us.

Beam Geometry :

- Flange n° 1 : any position + height offset with flange n°2

- Flange n° 2 : any position

- Core : middle, offset, inclined position

- Welding (option): tacking or submerged arc welding

Control :

- HMI : touch sensitive display

- Remote access service

- Direct design file transfer : dstv, dxf…

Options :

- Second clamping machine for welding exclusively

- Fastening control on machine with two-hand control (remote control)

- Motorized roller transfer

- Reinforced structure for heavy version (beam linear density = 1500 kg/ml)

- Specific tool for box section

- Wireless HMI

- Tropicalization

- Automatic adjustment and tacking gantry

- Automatic flange standing up